Gilso-nite in Oil Gas Drilling

Gilso-nite is used in drilling mud fluids and oil well cementing. Gil-sonite, in a range of softening points and particle sizes, is a standard ingredient in oil-based drilling muds used in shales and other difficult geological formations.

In past years (until 1970), oil-based drilling fluids were widely used across the world, and due to excellent shale recovery, filtration properties, and high resistance for chemical contaminations, there were so popular. However, by passing the time and appearing more considerations on environmental issues, water-based drilling fluids became more common throughout the world . The high- performance drilling fluid needs to be environmentally acceptable, too. Therefore, water-based muds are at the center of attention for development, but these types of muds need special and tailored-made agents to qualify drilling fluids functions in the best manners. Mentioned functions are summarized as below:

Nowadays, based on the significant usage of nanotechnology in different fields of science, applying nano-materials in oil and gas drilling is growing, too. Nano-particles are a perfect choice for drilling fluids agents because they have a special physio-chemical property. This property qualifies them for the high-performance drilling fluids requirements. Nano-sized particles have a high surface area to volume ratio in comparison with common agents in drilling fluids which are typically micron-sized, and this has led to enhancing drilling mud properties . Researchers have been successfully used nano- materials in different types of drilling fluids to improve the mud cake structure, lower the fluid loss, and reduce unwanted torque forces in the drilling operations so far.

One of the less-studied multifunctional agents used in drilling fluids is Gilsonite. Gilsonite is a naturally occurring bituminous asphalt. Natural Bitumen varies in composition depending upon its origin, history of formation and the geographical region, and presence of other minerals such as Sulphur. Gils-onite has been used in the mining industry as an additive in oil drilling fluids or well. The Gilsonite average molecular weight is significantly higher in comparison with other asphaltic additives used in the drilling fluid industry and other types of bitumen or resins. This high molecular weight makes Gilsonite a “semi-polymeric” material that can be used as a high-performance surface covering agent.

As water-based drilling fluids are mainly suitable for drilling in low-pressure, low-temperature (LPLT) conditions, while they may fail in high-pressure, high-temperature HPHT conditions, due to gelation or degradation of polymers. Therefore, adding Gilsonite can effectively improve water- based or oil-based drilling fluids performance in extreme temperatures in favor of its low cost.

In conclusion, Nano-Gilso-nite effects in water-based drilling fluids are investigated to design a possible high-performance drilling fluid. Then, the concentration of Nano- Gilsonite usage in water-based drilling fluids was investigated and optimized. More specifically, this paper tries to discuss the effect of Nano-Gilsonite on the prevention of drilling tools sticking problems with an experimental prospect.

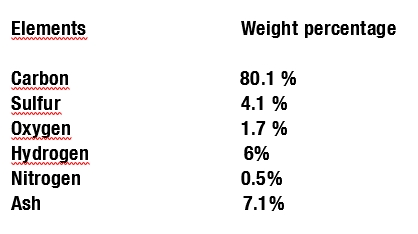

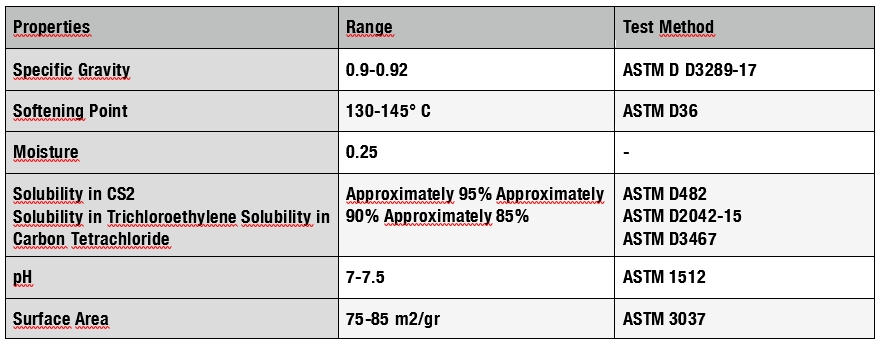

The Gilsonite powder sample used in this study was provided by a mine located within a 15 km distance south of Kermanshah province in Iran. Then, it was crushed to nano-particles with a ball-mill method. Chemical analysis was performed on the obtained powder, as shown as following

In conclusion, physical and chemical characterization of used Nano-Gilsonite showed these specific properties:

Besides, the proposed Nano-Gilsonite was used in low concentrations and without requiring any special surfactant in the drilling fluid. Nano-Gilsonite disperses quickly and easily in water-based with only mild agitation.

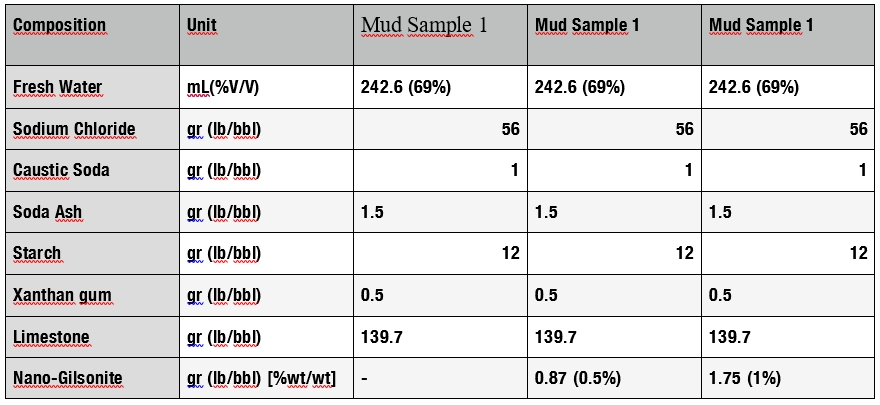

A simple polymeric mud was used for the initial formulation of blank fluid. It includes freshwater, salts, viscosifiers, and fluid loss controllers (mud sample1). After mixing required mud additives in the fluid phase, the mud’s pH was adjusted to 9.5- 10.5 using NaOH to keep the mud in the alkaline range. This blank mud was used as a representative drilling fluid containing micron-sized particles for comparative evaluation of rheological, HPHT/API filtration, and mud filter cake properties of the nano- based fluids. The nano-fluids (mud samples 2 and 3) had the same formulation as mud sample 1 in addition to Nano-Gilsonite with concentrations of 0.5 and 1% wt./wt., respectively. The mentioned formulations are given as following:

Also, a simple bentonite mud was used as a simple drilling fluid for comparing and evaluating of sticking pipe properties of the nano-based drilling fluids that are studied in this paper . The nano-fluids had the same formulation as mud sample 4 in addition to Nano- Gils-onite with concentrations of 0.5, 1%, and 2% wt/wt, respectively. Using this type of blank fluid is because of its high fluid loss and high pipe sticking characteristic in high pressures.

Gi-lsonite is added to bitumen-based paint to increase hardness, adhesion. UV stability, and water and chemical resistance. Gilsonite paint formulations are often used on automobile frames and radiators. Natural asphalt is also an ingredient in wood stains.

Gil-sonite can be used in the manufacture of paints. This material is used in paints based on bitumen. The high nitrogen content in the Natural asphalt increases tackling properties and stability against ultraviolet radiation. This product is mainly used for painting the exterior surfaces and to create acid resistance. It is used for painting the chassis of cars and metal structures.

Gi-lsonite can be used as the first carbon wetting agent in the black ink for newspapers and magazines. High concentrations of gilsonite are used in printing inks for newspapers. Basically, this material is used for dispersion of carbon black particles which make up the printed black ink. Moreover, it can be used in paints for wood as a dark brown paint. Due to its unique chemical and physical properties, gilsonite can transmit useful features to paints and polishing agents.

Gilso-nite or Natural Bitumen is readily soluble without heating in aromatic solvents (benzene, toluene, and xylene) and the majority of chlorinated solvents. It is also soluble without heating in aliphatic and low aromatic solvents (paints and another naphtha; ink oil, and diluents) but the mixing time is longer. The atomized grade is recommended for use without heating.

For use in dyes, the Gilso-nite is usually used in combination with bitumen (asphalt). In most cases, if you are using Gilsonite only, the final paint coating will be very rigid and brittle after drying. If only the conventional straight-run bitumen is used, the final paint coating will be is too soft and sticky. Therefore, a combination of gilsonite and bitumen shall be used to achieve the desired hardness (penetration) and the final drying time. Besides giving rigidity to the paint, gilsonite also improves the following:

Stickiness;

Shine;

Chemical stability;

Water resistance and

The consistency of paint

Gilso-nite resin is often used as the primary carbon black ink, news ink, and headset, and gravure inks. Gilso-nite resin is a good competitor to petroleum, phenolic and thin metal wire hydrocarbon resins, which can act as a complement or replacement to all of them. Keep in mind that several concentrations of Gilsonite or Natural Bitumen resin are used for durable news inks with better gloss and adhesion properties. On the other hand, distinct grades of certain species of Gilsonite called select are used in the formulation of black inks as well as additives in asphalt paints and polishes.

N-Asphalt is used to extract black and opaque brown pigments, which are used to make printer inks. Powder Gilsonite is widely used along with carbon black to produce black ink and gravure ink. N-B resin of MONAMORCO competes very well with petroleum-based hydrocarbon resins, phenolic resins, and metal resins, which can be used with different concentrations at all costs. Different concentrations of this substance are used to produce special inks with high luminosity. A special type of Gilsonite is also used in the manufacture of asphalt black paints and polished oils.

Natural Bitumen can also be used to prepare a black-brown colored solution that is used in bitumen coating gas, sewage, etc. This product is used in covering exterior surfaces, as well as to create acid resistance of surfaces, car chassis coating, coating of metal structures. It is also used as a low-cost alternative to other resins in black ink compounds.

In this field(painting), the company has succeeded in producing products with suitable quality for use in the paint industry, as well as in the production of rubber called Gilsonite micronized powder – rubber and paint additive. The company’s product is used in domestic paint and rubber companies after the relevant tests.

Properties such as durability and moisture resistance of asphalt concrete significantly improve pavement service life. When siliceous aggregate is used, then preventing moisture damage and stripping become distinctly required. Typically, stripping could be prevented by either using antistripping agents or by modifying the binders. The anti-stripping agent achieve its purpose by changing the aggregates’ affinity for water through changing the zeta potential (promote bitumen adsorption due to negative surface charge). On the other hand, modifications of binders promote interface bonding between aggregate particles and bitumen.

However, the process of applying anti-stripping agents or adhesion promoters is typically costly and, in some cases, may negatively impact other performance characteristics of pavement. Accordingly, this paper examines the merit of applying natural bitumen or Gilsonite instead of typically used anti-stripping chemicals in order to both promote resistance to moisture damage and reduce construction cost in asphalt. In addition to being quite low-cost, Gilsonite has a chemical composition nearly similar to that of petroleum based asphalt which makes it very compatible with asphalt binder.

Moisture-induced damage is one of the main distresses of flexible pavement. The main mechanism of this distress is due to de-bonding of bitumen and aggregates caused by the presence of water. Bonding between bitumen and aggregates occurs mainly by polar components in bitumen bonding with active aggregate sites through mainly hydrogen bonding and Van der Waals interactions. It has been also reported that aggregate properties have higher impacts than bitumen characteristics on interfacial adhesion. In terms of bitumen components, aromatic hydrocarbons have less affinity to bond to aggregates than polar asphaltene and resins.

In addition, the functional groups that have stronger adhesion to aggregate active sites are carboxylic acids, sulfoxides, 2-Quinolone types, ketones, phenolics and nitrogen compounds.

Among the aforementioned groups, carboxylic acids provide the strongest bond with aggregate surfaces, but they are easily substituted with water. Sulfoxides and 2-Quinolone types have similar chemical behavior (Huang et al., 2005). It should be noted that the effect of the aforementioned functional groups are related to the types of aggregates. Siliceous materials are hydrophilic and their asphalt coating can be easily substituted with water, while the bitumen coating of limestone aggregates cannot be detached easily by the presence of water. Accordingly, some researchers used Fourier Transform Infrared spectroscopy (FTIR) and surface ionization to track the elements leaching from aggregates into the awater and examine surface mineralogy of stone particles after stripping occurred.

It was observed that most stripped aggregates had less calcium, sodium and potassium on their surface where stripping was noticeable, indicating that stripping was accompanied by a significant cation dissolution. Other studies showed the addition of liquid anti-stripping agents could enhance interfacial bonds via polar ends of an anti-strip additive, which interact with the aggregate surface. It has been reported that among bitumen components, polar asphaltene and resins have a high affinity to bond to aggregates. Since natural bitumen has a significant amount of polar components, including asphaltene and resins, this study examined its effectiveness relative to commonly used additives (such as lime) to improve bitumen-aggregate adhesion strength, particularly when exposed to water.

Natural bitumen is a crude-oil-based substance that moved upward from underground rock reservoirs to the earth’s surface by passing through earth fractures. If natural bitumen reaches the earth’s surface, it will create bitumen springs; if it remains near the earth’s surface, it will gradually oxidize, solidify and finally turn into a solid, stiff substance named mineral bitumen. Gilso-nite is a black and brittle mineral bitumen that can easily be crushed into powder. Gils-onite, which is also called natural bitumen, asphaltite, uintaite, or asphaltum, is similar to hard petroleum bitumen. It is a resinous hydrocarbon that belongs to the hydrocarbonic class in modifier classification.

Gil-sonite can be used in asphalt mixtures either by premixing with bitumen before blending with aggregates or blending directly with aggregates prior to addition of bitumen. It has been suggested that wet process modification provide more prominent effect on the mechanical properties of asphalt mixture. Gil-sonite increases the viscosity of bitumen and reduces its penetration. Also, because of its higher softening point, gilsonite has higher stiffness compared to conventional bitumen (approximately 50 times higher than conventional bitumen). The results of a study conducted by Aflaki and Tabatabaee have revealed that increasing the content of Gilsonite in bitumen increases the viscosity and improves the high-temperature performance of bitumen.

However, gilsonite has a negative effect on intermediate and low-temperature performance. Other studies have also shown that the introduction of gilsonite to asphalt can improve high-temperature performance of bitumen, while it causes brittleness in the lower-temperature range, resulting in thermal cracking of asphalt concrete. The results of research conducted have also shown that increasing the gilsonite content improves resistance to rutting. They concluded that application of gilsonite has an effect on high- temperature performance of bitumen similar to that of polymers such as Styrene-Butadiene-Styrene (SBS). It should be noted that use of gilsonite is more cost effective than polymers, especially considering the shortage of butadiene supply that has led to a further increase in SBS cost.

Thus, understanding the behavior of this material as a bitumen modifier is important, because not only does it improve the performance of asphalt concrete, it also reduces construction cost. used gilsonite as an intermediate layer to reduce stress concentration. This way, asphalt concrete acts as a three- layered composite mixture in which coarse aggregates are coated with a thin film of stiff gilsonite before being mixed with the bitumen. The results of their study showed improvement in resistance to moisture.

However, the incorporation of gilsonite as an intermediate layer is not practical, because it is often accompanied by some difficulties such as dissolving in trichloroethylene to provide cover for aggregates. However, the moisture sensitivity of asphalt concrete fabricated with gilsonite-modified bitumen has not been evaluated. In this paper, FTIR spectroscopy and Indirect Tensile Strength (ITS) tests are used to evaluate the moisture sensitivity of gilsonite-modified mixtures. It is hypothesized that FTIR spectroscopy may help identify functional groups that can affect the moisture susceptibility of asphalt mixtures.

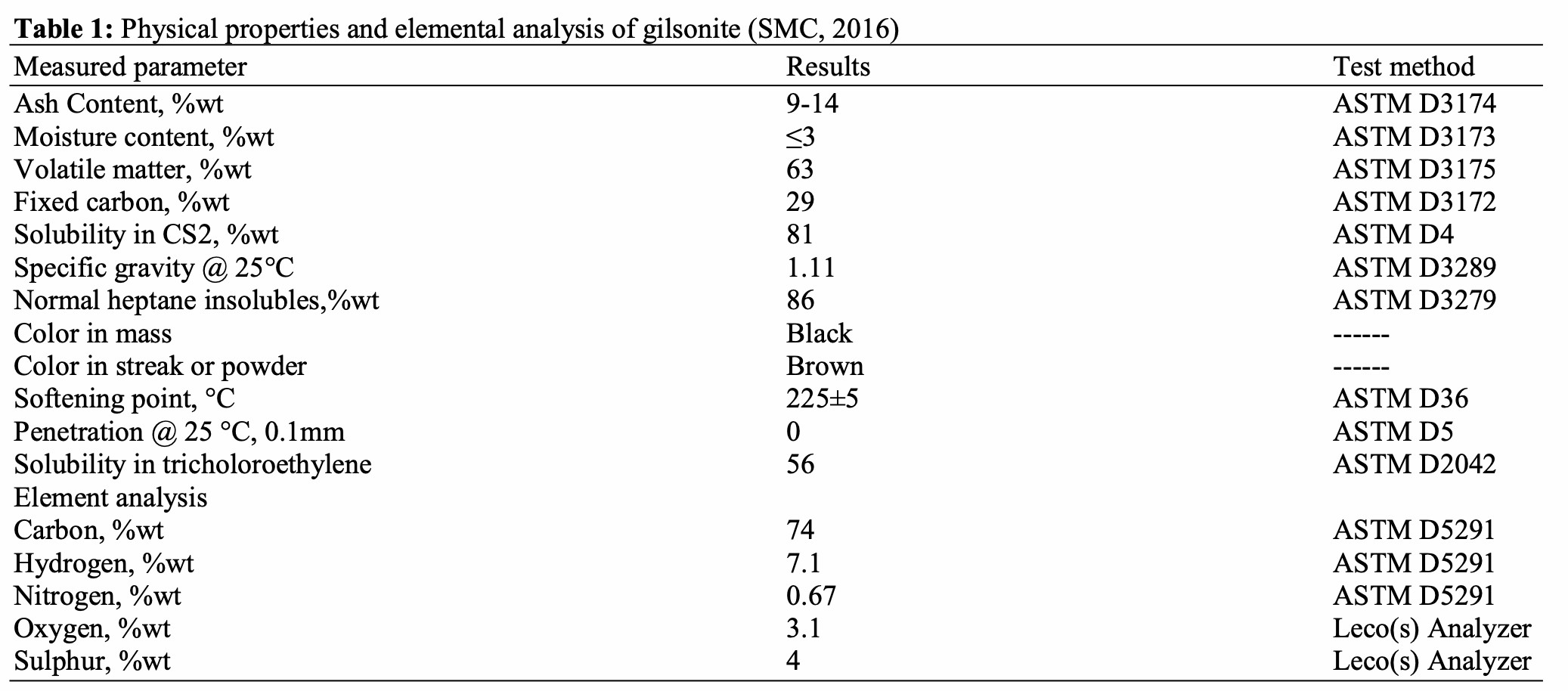

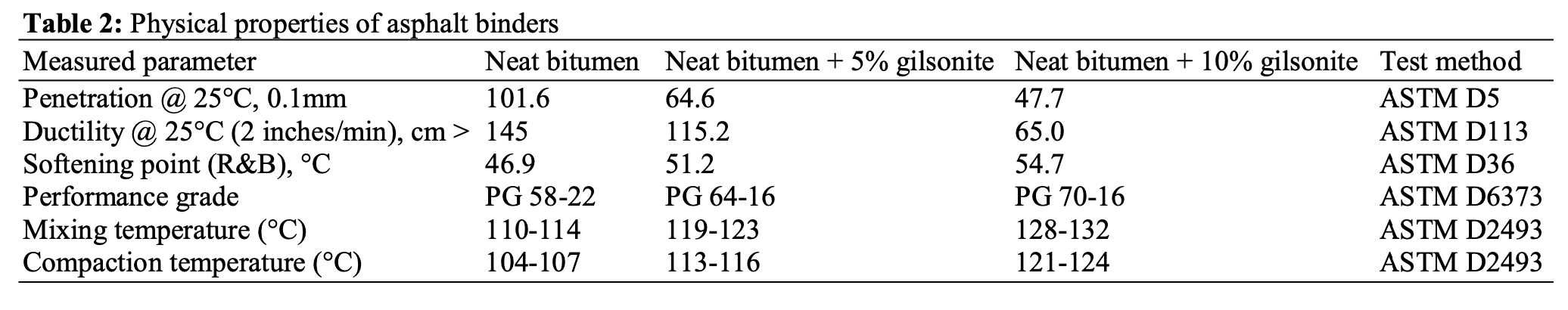

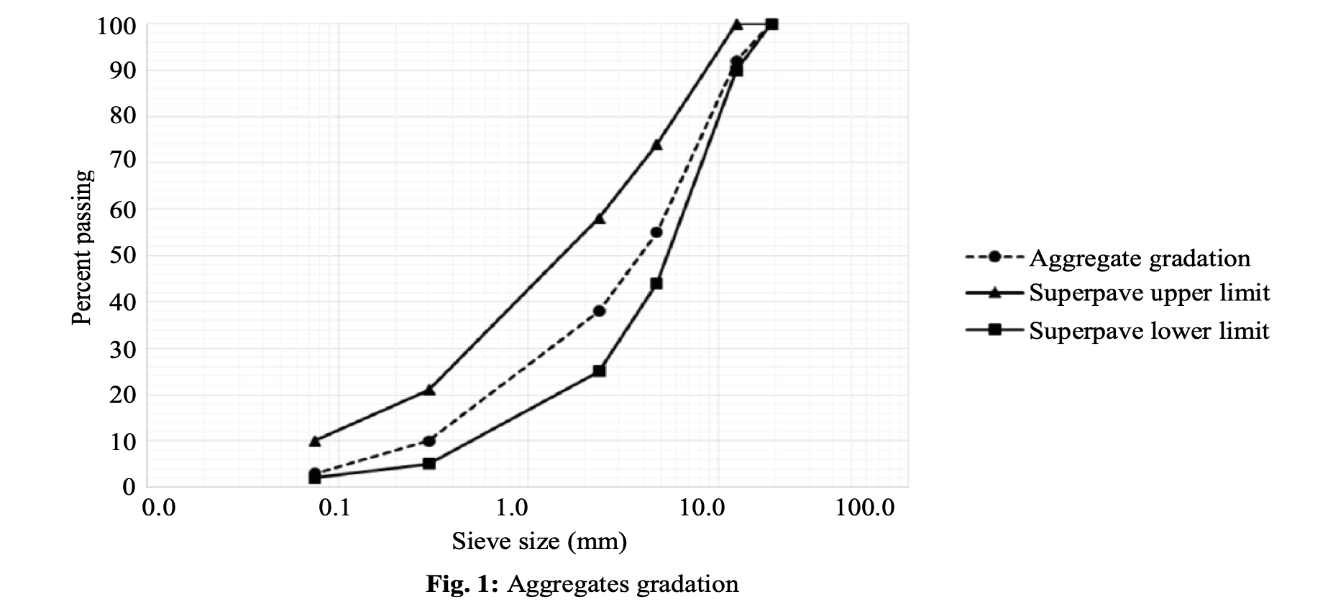

Crushed limestone aggregates and siliceous aggregates were used in this study; the aggregates were acquired from east and west of Tehran mines. The selected gradation for both aggregate types is presented in Fig. 1. Nominal maximum aggregate size was selected to be 12.5 mm. Also, neat bitumen with a performance grade of PG 58-22 and 200 mesh gilsonite powder were used. Detailed properties of asphalt binders and gilsonite are presented in Table 1 and 2.

To prepare samples, 5 and 10% gilsonite (by weight of bitumen) was added to the bitumen and heated to 180°C. The mixture was blended at 6500 rpm for 60 min in a high-shear-rate mixer. Then, optimum bitumen content for an unmodified mixture was determined according to the Superpave mix design, assuming a design high air temperature of 39-40°C.

Results and Discussion

Fourier Transform Infrared Spectroscopy and Indirect Tensile Strength tests were conducted according to the aforementioned procedures. In the following, the test results are interpreted.

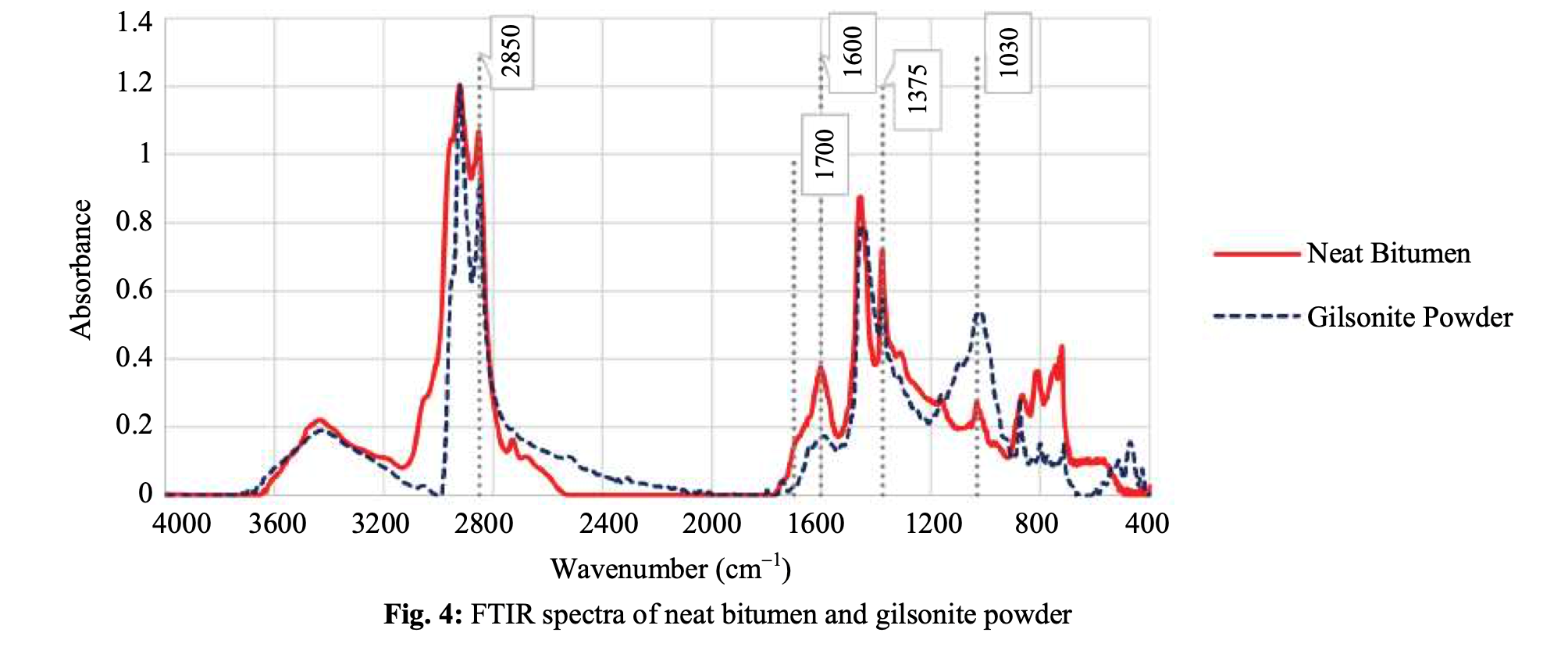

As established in the introduction in detail, FTIR spectroscopy and functional group indices of bitumen may help us to anticipate moisture sensitivity of bitumen-aggregate. Infrared spectra of the neat bitumen and gilsonite powder are presented in Fig. 4. Both spectra have been normalized with respect to intensity at 2920 cm−1 wavenumber. The similarity of the spectra in wavenumber domain of spectroscopy and especially at 2920, 2850, 1600, 1455, 1375 and 1030 cm−1 is noticeable in this figure. Both samples show peaks at these wavenumbers. Absorbance at 2920 and 2850 cm−1 are related to asymmetric and symmetric C-H stretching vibrations, respectively. The peak intensity at 2920 cm−1 indicates the presence of long aliphatic chains in both gilsonite and refined bitumen. As shown in Fig. 4, there is no distinct intensity peak at 1700 cm−1 relating to carbonyl compounds for gilsonite powder.

Top intensity at 1600 cm−1, which is related to stretching vibrations of the C=C double bond of aromatics, can be identified for both gilsonite powder and neat bitumen. However, this peak intensity is more prominent for neat bitumen. Peak intensity at 1450 and 1375 cm−1, due to deforming vibrations of asymmetric and symmetric C-CH3 bonds, are noticeable for both materials. One of the differences between gilsonite powder and neat bitumen is the high intensity of the peak at 1030 cm−1 relating to sulfoxide group.

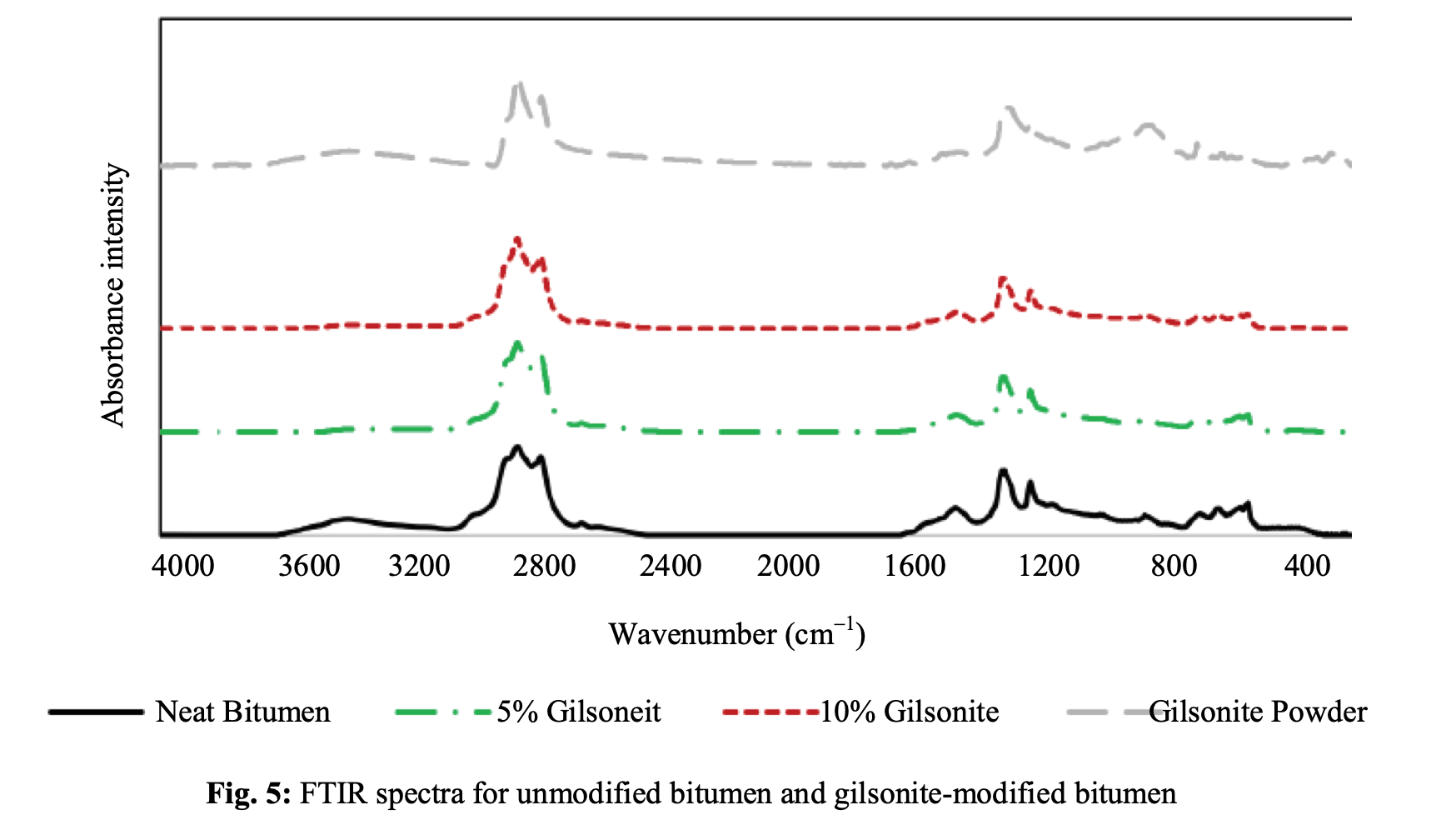

This finding is consistent with the results of elemental analysis of gilsonite powder presented in Table 1. Peaks between 700 to 900 cm−1 wavenumbers, which are related to aromatic compounds, are also noticeable for both gilsonite powder and neat bitumen. As just discussed, there are many similarities between functional groups of gilsonite powder and neat bitumen (especially at wavenumbers above 1400 cm−1). This result conforms to the gilsonite formation hypothesis which states that gilsonite is a natural bitumen-based material. Figure 5 shows FTIR spectra for unmodified bitumen and gilsonite-modified bitumen

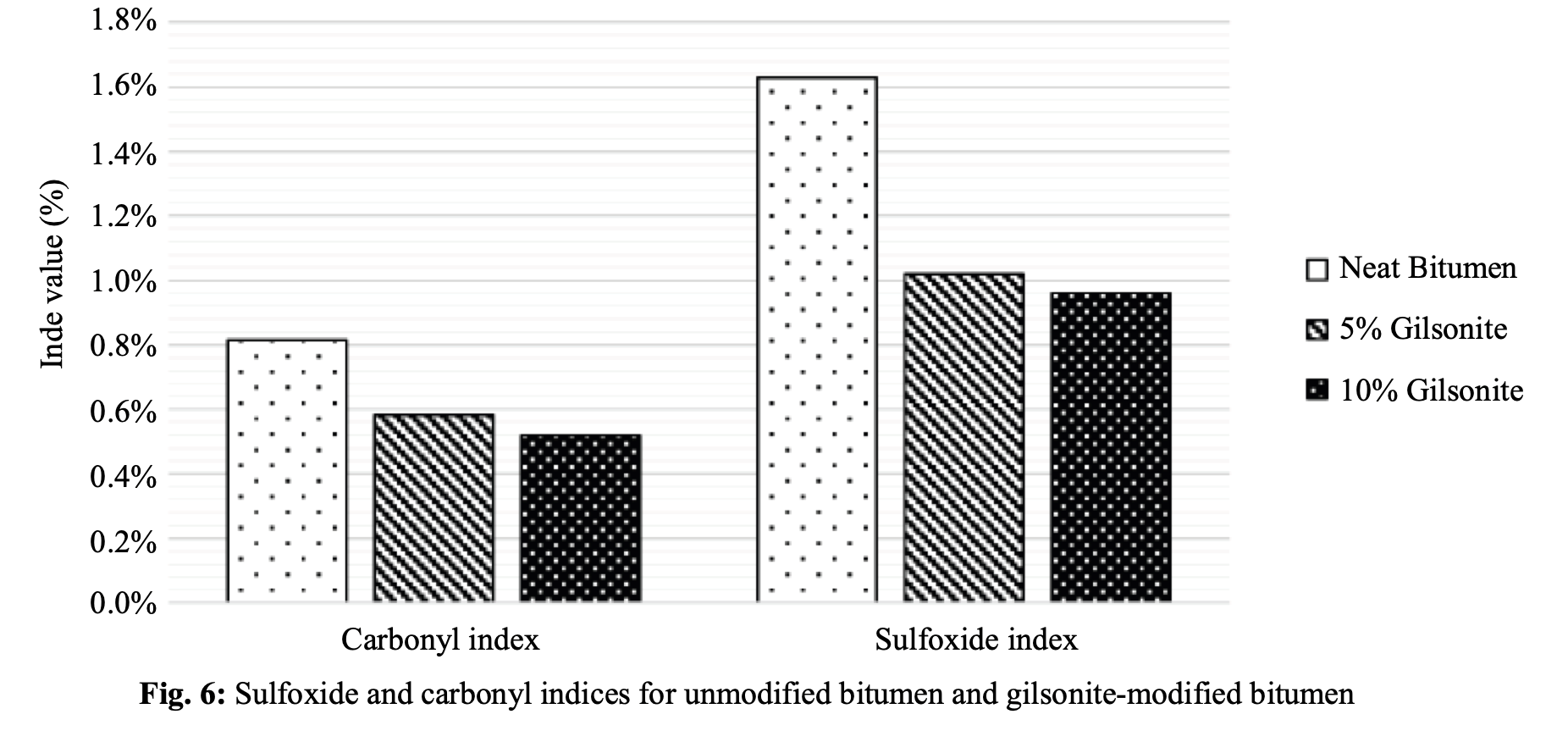

For quantitative evaluation of these spectra, spectrometric indices have been used; the results are presented in Fig. 6. It can be observed that both carbonyl and sulfoxide indices are decreased by blending gilsonite with neat bitumen. Since a high-intensity peak was observed for gilsonite powder in Fig. 4 at 1030 cm−1, the decrease in sulfoxide index was not expected. It seems that increases in other aliphatic functional groups and asphaltenes have resulted in an overall reduction of the sulfoxide ratio in the bitumen. As it was discussed in the introduction part, an increase in sulfoxide groups and carboxylic acids of bitumen will result in lower moisture resistance of asphalt concrete. Thus, it can be deduced that blending gilsonite with neat bitumen will result in reduced moisture sensitivity and increased Tensile Strength Ratio (TSR) for asphalt mixtures.

Conclusion

Gilso-nite is a mineral material that has a lower price than bitumen. Natural Asphalt can be used as a modifier of bitumen to improve performance-related properties of asphalt concrete. In this study, the moisture sensitivity of gilsonite-modified mixtures was evaluated using Fourier transform infrared spectroscopy and modified Lottman tests. The results of this study are as follows:

TSR values than control asphalt mixtures which results in higher resistance to moisture damage. Therefore, the use of gilsonite-modified mixtures is recommended in humid areas